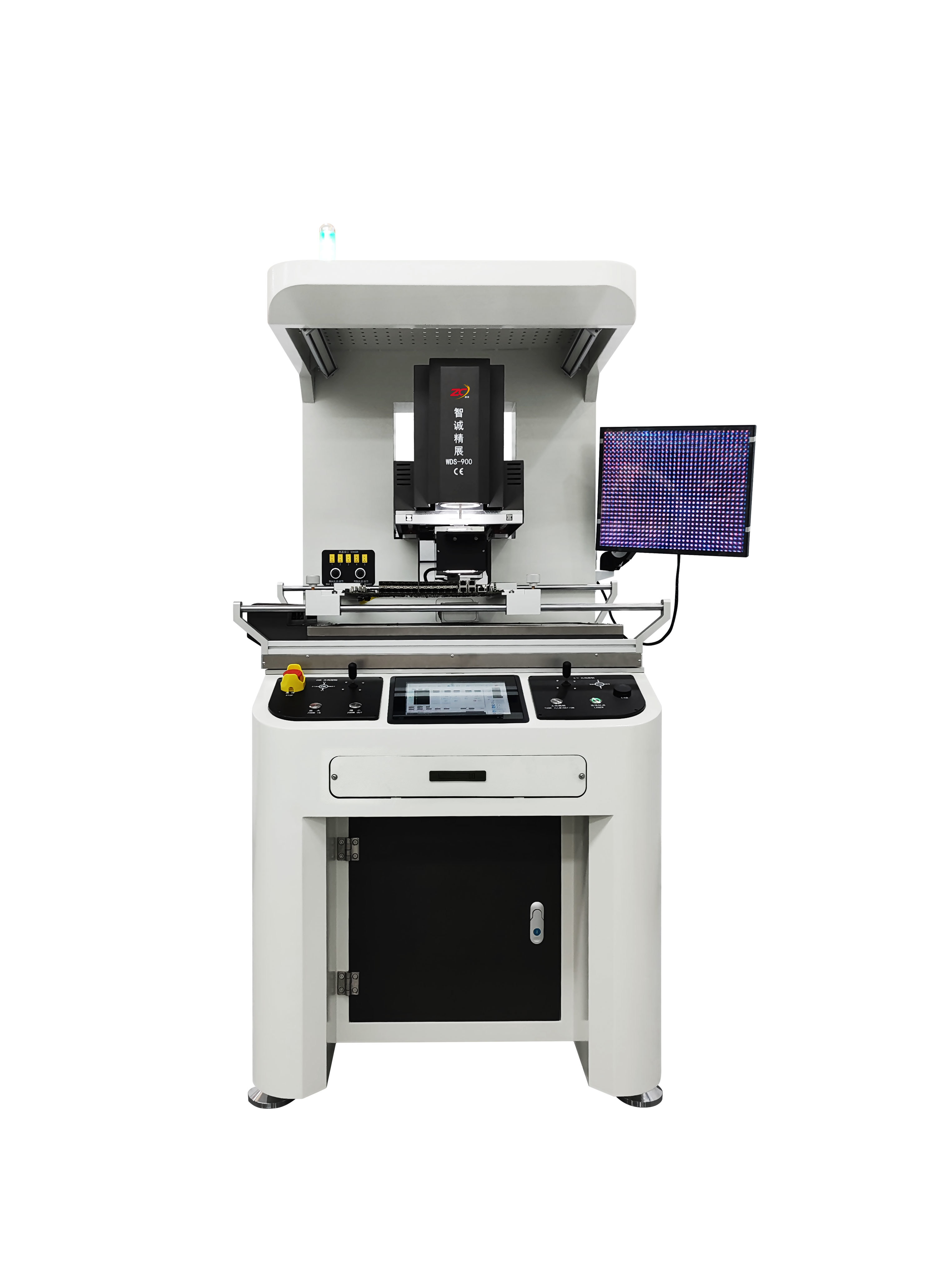

BGA rework equipment is essential in electronics manufacturing and repair. It is designed to handle Ball Grid Array components. This equipment enables precise removal and replacement of BGAs. It typically features temperature control for soldering and desoldering, ensuring reliable connections. With advanced features, it helps improve the quality and efficiency of electronics work.

BGA rework equipment is a crucial asset in the electronics industry. It is specifically designed to handle Ball Grid Array (BGA) components, which are widely used in modern electronics.

This equipment offers precise control over the rework process. It features accurate temperature regulation, allowing for the perfect melting and solidification of solder during operations such as soldering and desoldering of BGA components. The ability to set exact temperatures ensures that the integrity of the BGA and the surrounding circuitry is maintained.

The BGA rework equipment comes with specialized tools. These include well - designed nozzles that can be adjusted to fit different BGA sizes and shapes. This adaptability makes it suitable for a wide range of BGA - based components, from small - scale consumer electronics to larger industrial - grade circuit boards.

In addition, modern BGA rework equipment often has user - friendly interfaces. Technicians can easily operate and program the equipment for different rework tasks, saving time and effort. Overall, BGA rework equipment is indispensable for any electronics repair or manufacturing facility that deals with BGA components.