A BGA desoldering station is a crucial tool in electronics repair and manufacturing. It is designed to precisely heat and remove Ball Grid Array (BGA) components. With adjustable temperature and air - flow settings, it ensures efficient desoldering without damaging the circuit board. It is a must - have for technicians dealing with complex electronic devices.

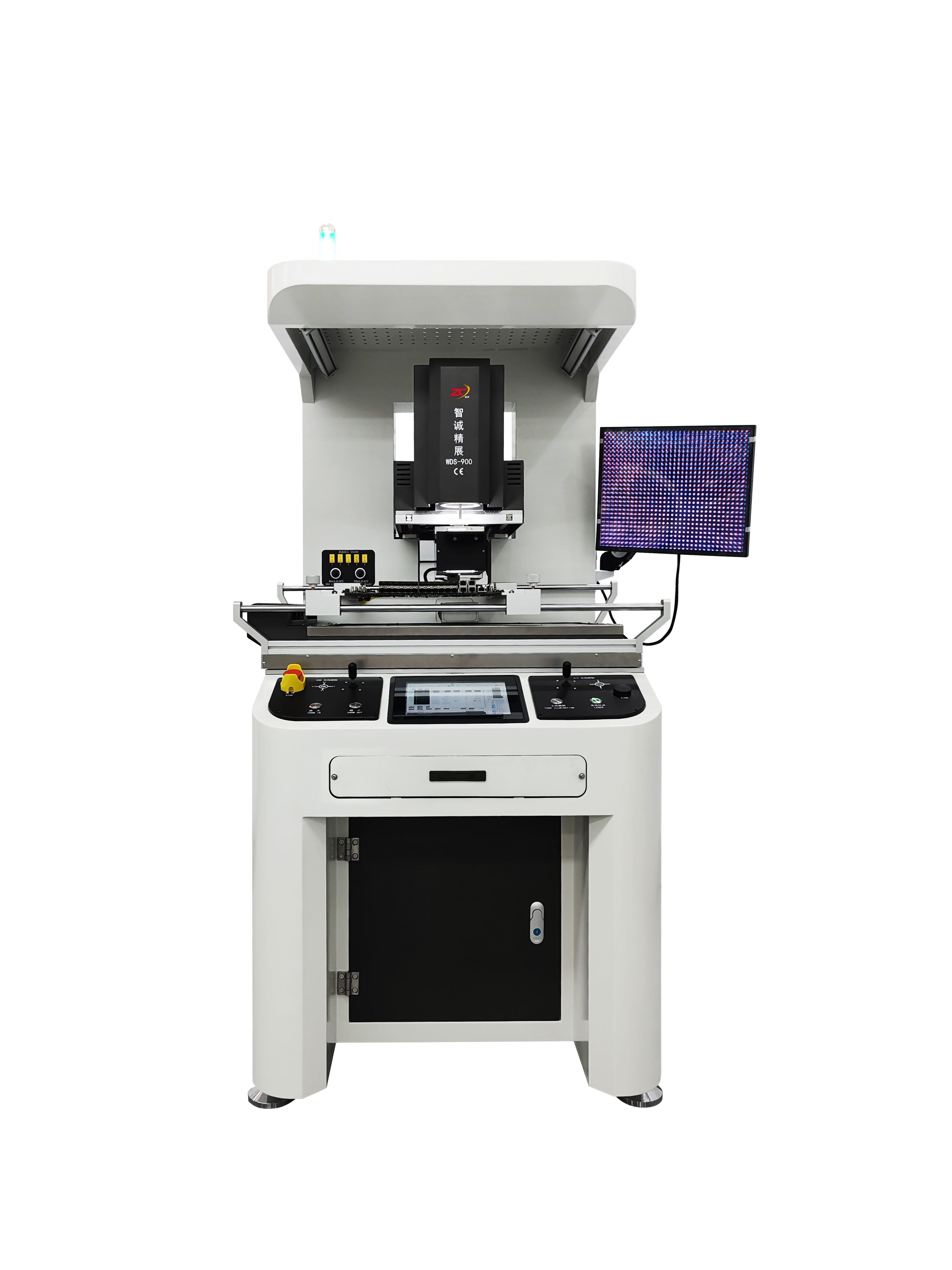

The WDS-900 BGA Desoldering Station is a powerful, software-controlled rework solution designed for high-precision PCB repair. Compact in size but highly capable, it supports large motherboards up to 760×630mm, making it ideal for industrial and advanced electronics applications.

Equipped with a 9000W infrared bottom preheater, 1600W upper and lower hot air systems, and independent triple temperature zones, the WDS-900 delivers fast, uniform heating and efficient cooling. It features a three-in-one heating mode (hot air + infrared + optional nitrogen/air), supporting a wide range of chips including BGA, QFN, LGA, POP, and CSP.

All movements are electronically motor-driven and joystick-controlled, including PCB alignment, head positioning, and X/Y-axis adjustments. The optical alignment system with 22x zoom, autofocus, and color-difference resolution ensures pinpoint accuracy, while built-in vacuum suction with pressure control simplifies chip placement.

With a 10-stage heating curve, the WDS-900 stores over 100 temperature profiles and automatically generates optimal soldering/demolition curves—perfect for lead-free processes and mass rework. Additional features include a side-view camera (optional), temperature monitoring sensors, and titanium alloy nozzles with 360° rotation.

Robust, intelligent, and user-friendly, the WDS-900 BGA desoldering station sets a new standard in efficient, professional PCB repair.